PRODUCT LITERATURE

Our Manuals, Brochures and Lubricant data sheets are available below for your convenience. Please contact us for additional resources and questions.

Main Literature

Manufacturing has a lot of moving parts, which is why reliable, top of the line lubrication and equipment is essential for the smooth operation of your business.

Conveyor Lubrication Systems

Digilube manufacturer’s a complete line of automatic programmable conveyor lubrication systems to lubricate various type of overhead and in-floor conveyors.

Conveyor Lubrication Systems Manuals

Conveyor Lubrication Systems Brochures

DL-60 Powered Brush Cleaner

Digilube Systems offers powered conveyor chain & rail brush cleaners for a wide range of conveyor types. Two common types used in the finishing industry that require cleaning are I-Beam and Enclosed Track conveyors.

Power Brush Manuals

| DL-60 Powered Brush Cleaner – 3 inch |

| DL-60 Powered Brush Cleaner – 4 inch |

| DL-60 Powered Brush Cleaner – 6 inch |

| DL-60 Powered Brush Cleaner – Enclosed Track |

Conveyor Brush Brochures

ATS Electro-Lubers Installation Manuals

Digilube Systems is the largest U.S. Stocking / Re-filler Distributor to ATS Electro-Lube. We stock 30+ brands of major grease companies and fill to our customers needs. If you don’t see what you are looking for, give us a call.

Manuales en Español

Below you can find a few manuals and brochures translated in Spanish.

| Lubricador Viga-L |

| Lubricador de Pista Cerrada |

| DL-60 Manual de 3 Pulgadas |

| DL-60 Manual de 4 Pulgadas |

| DL-60 Manual de 6 Pulgadas |

| Aplicaciones para Procesamiento de Aves de Corral |

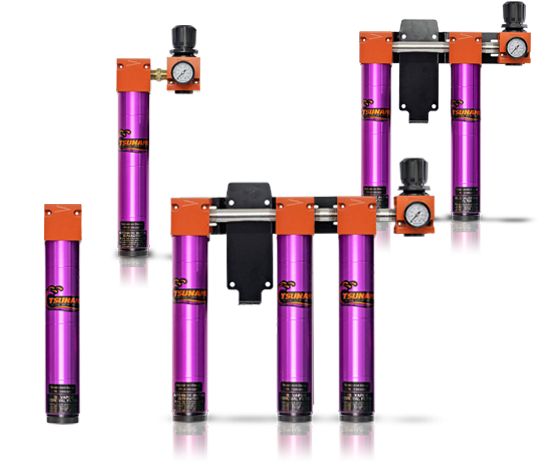

Air Filtration Brochures

We offer Air Filtration options to accommodate any application.